Going to Plattling to choose the coating was great since it gave us a chance to select the colour of the glass in person. We used to have to choose the glass from a catalogue with a limited range of options, instead of seeing the custom glass on the actual building.

When heading up large-scale projects, architects must have a clear vision of the future as well as a concrete and precise idea of the final result so that they can choose the most suitable materials. Selecting the type of glass is certainly one of the most difficult decisions. But until now, the range of coated glass products available on the market was limited.

Thanks to AGC and our exclusive Coating on Demand service, architects can now choose the colour they want for the glazing in a given project, see what it looks like on screen under real-life conditions, validate the colour on a sample and leave with a sample of their creation. Michele Tadini, the architect who designed the Hotel Porta Volta in Milan, Italy, was the first to experience this unique service.

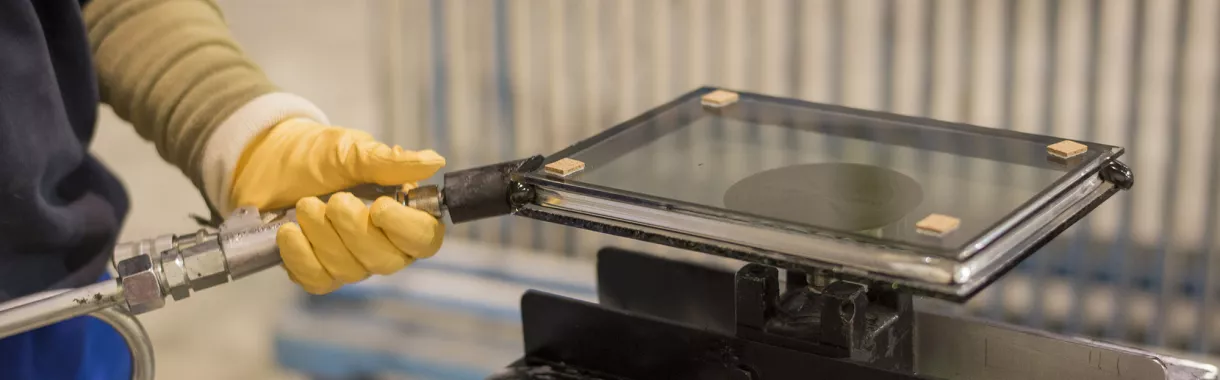

This process takes place during a one-day Coating On Demand session in Germany at the AGC Interpane plant, which specialises in coated glass. Using specially developed photorealistic simulation software, AGC allows architects to choose a typical building that resembles their project and to simulate the colour of the glazing. It is now possible to transform a vision, a dream into a precise image that includes specifically selected aesthetics! The software brings the project to life and allows the user to play around with colours, lighting and environments before transforming it into a representation that can be viewed from every angle. All parameters can further be fine-tuned by energy performance to ultimately define the ideal coated glass.

Michele Tadini recalls this unique experience: “Going to Plattling to choose the coating was great since it gave us a chance to select the colour of the glass in person. We used to have to choose the glass from a catalogue with a limited range of options, instead of seeing the custom glass on the actual building.”

Once the coating has been defined, AGC immediately produces this unique coating on the glass. In the afternoon, the newly defined coating is ready. The process finishes with the validation of the coating on a sample under real life conditions before handing it over to the architect. Your dream has come true.

“When glazing plays an important part in an architectural design, it is important to be able to customise the colour so that it can interact with the rest of the building,” Michele continues. “Our building features a lot of wood and greenery, so the cool green and blue tones of conventional glass did not really deliver the look we wanted. We were delighted with Coating on Demand. It is a great solution for architecture,” he concludes.

Antonio Viscardi, Owner of Hotel Porta Volta adds: “I’m delighted I came to see this plant and the coater. We think Coating on Demand can be a really valuable tool for promoting our building, since it resulted in a building where the glass matches the other materials, such as wood and greenery. We can also use it as one of our many marketing tools – online and otherwise – to promote the building.”

Today, the Coating on Demand service is available at the AGC Interpane Plattling site in Germany as well as the AGC Lodelinsart plant in Belgium, where the coating can be produced in both annealed and heat-treated versions.