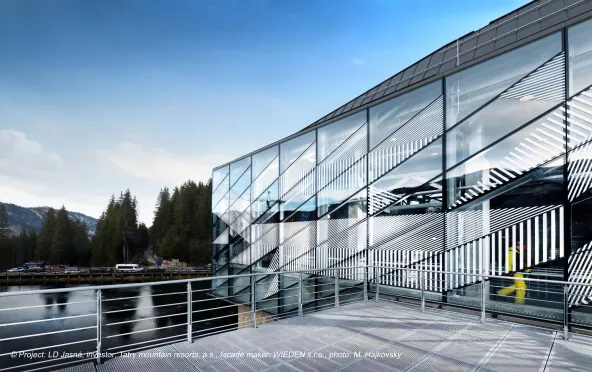

Contemporary architecture is dominated by neutral and natural hues, with the use of natural-looking materials currently the most prominent trend. Flashy colours are not often seen. And yet, the architectural design for the lower cable car station at the Jasná Ski Resort in the Low Tatras mountains of Slovakia is a delightful and surprising blend of both these approaches. By day, it is a model of simplicity and organic beauty, with the white printed graphics adding depth to the extra-clear glass facade. But when night falls, the illuminated shell of the building is transformed into a coloured crystal, delighting visitors with an extraordinary visual experience.

Building of the Year

The new cable car in Jasná streamlines and expedites the transport of visitors from Biele Pút' to Priehyba and Chopok in both the winter and summer seasons alike. Construction work on the new cable car began in September 2021. The stated goal of the investor, Tatry Mountain Resorts, was to make transport to Mt Chopok significantly faster, easier and more environmentally friendly. But in addition to providing comfort and speed, it is also a visual treat for architecture buffs. The project for the lower cable car station at Biele Pút' not only received the Building of the Year 2022 Award in Slovakia for its exceptional and progressive design, but also won the Public Choice Award in the online voting.

Neutral base layer for digital printing

The 1,500 m2 of double glazing specified for the project was manufactured at the AGC Processing plant in Teplice, Czech Republic. Extra-clear, low-iron Planibel Clearvision glass was used not only to ensure higher light transmission and a neutral look, but also to showcase the graphics prepared at the HELUZ IZOS plant using state-of-the-art technology. During the printing process, ceramic ink is applied to the glass sheet. Once the ink is dry and has been checked visually, it is permanently baked onto the surface of the glass in a tempering furnace that has been evenly heated to around 620 °C. The final print is colourfast and remains unchanged even when subjected to adverse weather conditions and UV radiation. It is also resistant to abrasion, scratching and fluctuating temperatures. The sophisticated graphic design was created by Lasvit. Since multiple print designs were used, each of the nearly 500 sheets of insulating glass is practically an original piece of art. The facade’s structural components were designed by the architects and engineers at SIAL, in collaboration with representatives from facade-maker WIEDEN.